Stainless Steel & High Alloy Metals

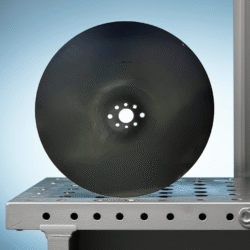

Cold saw blade guide to cutting stainless steel & high alloy metals

Stainless steel and metals like tool steel, Inconel, and titanium are very tough. They can handle high heat and are very abrasive. Using the wrong blade can cause problems like glazing and chipped teeth.

This guide will help you choose the right blade. It depends on the type of saw, the material thickness, and the amount you cut. You’ll get clean cuts and your blade will last longer.

What Are High-Alloy Metals?

High-alloy metals have more than 5% of alloying elements in them. These elements, like chromium and nickel, make the metals strong and resistant to damage. They are great for tough jobs, but hard to cut without the right tool.

🧪 Common Examples of High-Alloy Metals:

| Material | Key Alloying Elements | Common Applications |

|---|---|---|

| Stainless Steel | Chromium, often Nickel, Molybdenum | Food processing, medical, aerospace, and manufacturing |

| Chromoly (4130, 4140) | Chromium, Molybdenum | Roll cages, aircraft structures, and tools |

| Inconel | Nickel, Chromium, Iron | Jet engines, turbine blades, exhaust |

| Hastelloy | Nickel, Molybdenum | Chemical plants, marine equipment |

| Titanium Alloys | Titanium with Aluminum, Vanadium | Medical implants, aerospace, and racing |

| Tool Steels (M2, D2) | Tungsten, Vanadium, Molybdenum | Drills, dies, cutting tools |

Bestselling Blades

Why Blade Selection Is Critical

These metals are tough and can get even harder when cut. They also make a lot of heat when being cut.

To make clean cuts and last longer, you need:

- HSS or carbide-tipped blades

- Proper grind geometry (less aggressive rake, controlled relief)

- Correct cutting speed (SFPM) – Cold Saw SFPM to RPM Calculator

- Premium coatings like TiN or TIALN to reduce wear and heat

How We Help at ColdSawShop.com

When you pick “stainless steel” or any high-alloy material, we set up your blade. We choose:

- Material type

- Rake & relief angle geometry

- CBN ground tooth finish

- Optional coatings based on saw type and use case

We make blades that last, even when the material is hard to cut.

Manual Cold Saw (Under 120 RPM)

Coating Options:

- TiN Coating – Recommended for all stainless jobs

- TIALN Coating – Not necessary for manual saws, but offers the best thermal stability if you’re pushing the limits

Speed Tip

Your RPM should be 50–130 SFPM, depending on what you’re cutting:

- 50–90 SFPM for solids

- 90–130 SFPM for hollow tube

- Use our SFPM-to-RPM chart to check your machine’s speed.

Blade Geometry:

For cutting stainless steel, we use a less aggressive blade than for carbon steel. Manual saw blades have a 12° positive rake and a 6° relief. This makes them last longer and helps control chips.

Semi-Automatic Cold Saw (Under 120 RPM)

Required Blade Type:

- TIALN Coated M35 Cobalt Blade

This is the top choice for cutting stainless steel. Semi-auto saws make more heat, so M35 + TIALN is best.

Why TIALN?

- It’s very strong against heat and galling.

- It has low friction for cleaner cuts and less burring.

- It makes blades last longer and work better for making lots of cuts.

Coolant Tip:

Always use a water-based semi-synthetic coolant when cutting stainless on manual or semi-automatic saws. It’s key for blade life and quality cuts.

Blade Geometry:

For semi-auto saws, we use a 14° positive rake and a 6° relief angle. This setup is great for aggressive but controlled cuts and better heat resistance.

Dry Cut Metal Saw (14″ Only)

We have a special stainless blade for 14″ dry cut saws. These saws run at ~1,300–1,500 RPM and need carbide-tipped blades made for stainless steel.

- 14″ Stainless Cutting Carbide Blade – TCG Grind

Woodworking Saws (Miter, Chop, Table Saws)

Do NOT cut stainless steel on high-speed woodworking saws.

These saws spin too fast, and stainless steel is too hard and hot for them. You will:

- Burn the blade

- Damage the saw motor

- Put yourself at risk

Blade Selection Summary

| Saw Type | Recommended Blade | Notes |

|---|---|---|

| Manual Cold Saw | TiN Coated M2 (baseline) | |

| Semi-Auto Cold Saw | TIALN Coated Blade | Highly recommended for production |

| Dry Cut Metal Saw (14″ only) | 14″ Carbide Tipped Stainless Blade | Only available size for dry cut stainless blades |

| Woodworking Saw |  Not Supported Not Supported | RPM too high; unsafe and ineffective |