Cold Saw Blade Guide

The Ultimate Cold Cut Saw Guide - Full resource for cold saw blade teeth requirements, material cutting tips, blade selection, speed charts and more

Cold saw blades are designed for precision cutting of metals with minimal thermal distortion. This document covers detailed processes for selecting the appropriate blade, calculating correct speeds and feeds, using proper cutting fluids, maintaining the blades, and resolving frequent issues. The concepts here are underpinned by our 40 years of experience and testing supported by industry-standard guidelines.

Rules-of-thumb and Good Advice

- Tooth pitch is measure as the distance from tooth tip to tooth tip. As a rule there should be 3-6 teeth in the cut.

- As a blade is resharpened, the tooth pitch is reduced. Therefore, retoothing can be necessary occasionally.

- The blade speed depends on the material to be cut. For the standard construction steel it should be about 50 rpm when using a 11″ blade.

- Feed is measured as the chip thickness per tooth per revolution (max. 0.1 mm – .004″) but is generally listed as inches per minute.

- Using the correct feed, the chips are bright, even in size and nicely rounded.

- Plenty of fluid must be used when cutting. Mixture 6-10%.

- Resharpened blades always have to be "run in". Make 6-8 cuts with normal speed and about 25% of normal feed.

- If "pick up" occurs, the blade should always be dismantled and retoothed.

- Thorough cleaning of the blade and flanges before mounting is very important and the backlash in the device pins taken out. This can be done by putting slight pressure against the face of the tooth in a direction opposite to that of the saw rotation as the blade is being clamped.

- When purchasing new blades, it is important to be aware of the blade material, bore tolerance, possible surface treatment and side run out.

- Circular saw blades should always be resharpened on machines that secure an even tooth pitch. Resharpening with coolant improves the blade life.

- Tooth geometry must be adjusted to the work piece. For example when cutting stainless and aluminum, special ground blades for these materials should be used.

Selecting # of Teeth

Number of teeth can also be listed as tooth pitch, which is the distance from tooth tip to tooth tip and is measured in millimeters.The tooth pitch used depends on the size and the material to be cut.In the table below the tooth pitch in mm is listed and in the table on the next page the number of teeth is listed.

| Material to cut | 10-20mm | 20-40mm | 40-60mm | 60-90mm | 90-110mm | 110-130mm | 130-150mm | 150-170mm |

|---|---|---|---|---|---|---|---|---|

| Cast Iron | 4 | 6 | 8 | 11 | 14 | 16 | 16 | 18 |

| Soft steel/ Alloy steel | 6 | 8 | 10 | 12 | 14 | 18 | 18 | 18 |

| Profiles: Wall thickn. 1/10 dia. | 4 | 6 | 8 | 11 | 14 | 16 | 16 | 18 |

| Profiles: Wall thickn. 1/20 dia. | 3 | 4 | 5 | 6 | 6 | 8 | 10 | 12 |

| Profiles: Wall thickn. 1/40 dia. | 2 | 3 | 4 | 5 | 5 | 6 | 6 | 6 |

| Solid stainless | 4 | 6 | 8 | 11 | 14 | 16 | 16 | 18 |

| Solid aluminum | 4 | 8 | 12 | 14 | 16 | 18 | 20 | 20 |

| Profiles aluminum | 4 | 6 | 8 | 10 | 10 | 12 | 12 | 12 |

| Plastics | 4 | 6 | 8 | 10 | 10 | 12 | 12 | 12 |

| Copper | 6 | 8 | 11 | 14 | 17 | 18 | 20 | 20 |

| Brass | 5 | 7 | 10 | 12 | 16 | 18 | 18 | 20 |

# of Teeth Table

Speed

The speed depends on the material to be cut and will be listed as either Surface Feet Per Minute (SFPM) or Revolutions Per Minute (RPM). Below is an example of RPM which is dependent of the blade diameter. A complete table with SFPM will follow on the next page to help with cold saw RPM| Material to cut | 200-250mm 8″-10″ | 275-300mm 11″-12″ | 315-350mm 12.5″-14″ |

|---|---|---|---|

| Mild steel | 65 | 50 | 35 |

| Med. hard steel | 50 | 40 | 30 |

| Stainless steel | 30 | 20 | 15 |

| Aluminum/Plastic | 1000-2500 | 800-2000 | 600-1500 |

| Copper | 400 | 300 | 200 |

| Brass | 500 | 400 | 300 |

Speed, Feed & Tooth Angles

Feed

Chip load per tooth is independent of the speed. The correct feed can theoretically be calculated from a chip load of 0.004″(0.1mm) per tooth per revolution. In practice, the maximum feed is determined by the stability of the machine, the clamping and the capability of the motor. The chips are also an important factor determining the feed and they should always be the correct color and shape. Basic feeds listed in inches per minute can be found in the table on the previous tab. This is the basic feed and it can and should be increased by production cutting on stable machines or by using special blades.Chips

- Too low a feed:

Proper chips are not formed, only "metal crumbs".

The blade is worn excessively and life is reduced.

- Too high a feed:

Discolored chips that weld in the gullets.

There is great risk that the blade will break.

- The correct feed:

The chips are nicely rounded, uniform and bright.

Maximum use and benefit of the blade.

Chips:

Fluids

Fluid is used for cooling, flushing away chips and lubrication.Use a recognized product and follow the suppliers instructions carefully. Sawing is a "hard" machining process that demands a mixture of 6-10%.Fluids should be applied in generous amounts on both sides of the blade during cutting. The nozzles must be pointed directly at the cutting point. The cutting process must never be commenced without fluids. If it is, the tooth tips will burn or "pick up" may occur, either of which reduces blade life substantially.Stability in fixture/vice

A stable circular saw is the most important basis for obtaining good cutting results.Stability must be present in the machines main bearings, column and vice. A lack of stability leads to vibrations in the machine and/or blade. This vibration leads to substantial loss of blade life or at worst blade breakage.For cutting various profile shapes or tubes, a special formed vice can be beneficial.Cleaning of Blades

Remember to clean both the blade and flanges well when mounting a blade. A single chip between the blade or flange can lead to excessive side run out as well as reduced machine stability and cutting quality.Running in

Always use "the run in procedure" for resharpened blades.Make 6-8 cuts with normal speed, but at only 25% of normal feed. Gradually increase the feed until normal feed is reached.The run in procedure hones the tooth tips removing the sharp fragile edges from the resharpening thus increasing blade life.Special Grinding & Tooth Forms

There are a number of special grindings and different tooth forms that can optimize the cutting process. The most important are: Tooth form A: Primarily used for non-ferrous cutting of thin walled profiles. Only ground on specific request from customers. Tooth form A W: Primarily used for non-ferrous cutting of thin walled profiles or cutting plastic materials and combination materials of plastic and aluminum. Tooth form B: Rarely used unless a very high number of teeth are used. Used for non-ferrous cutting, plastic cutting or friction cutting. Form B is a stronger tooth than Form A and AW but is also primarily used for cutting thin sections. Tooth form B W: Used for cutting profiles and work pieces in smaller sizes. All kind of materials. Ground as a standard with tooth pitch T. Tooth form C (HZ): Primarily used for cutting work pieces in larger sizes. Ground as a standard tooth pitch T≥5 mm as a standard. Tooth form C is a triple chip tooth form with pre cutter tooth and is self-centering. Chip breaker (Notch Grind): Ground on tooth form B. The tooth pitch has to be T>3.8 mm (.15″) and the kerf 2.2 mm (.087″). Used for cutting all kinds of materials. The tooth form is only used for cutting thin-walled profiles with a wall thickness of 1.5-2.5mm (.059″-.098″). Chip breaker tooth form increases the blade life, lowers the cutting time and reduces burrs. Should only be used for production cutting on stable machines. Standard no. 1: Used on both tooth form BW and C (HZ). A stronger tooth that increases life time on more demanding applications. Special tooth form: Tooth forms with altered tooth depths or angles can always be ground for special applications. Only ground on special request. The above tooth forms can be ground with specific angles for materials like stainless, aluminum, brass, copper and plastic.By using special types of grinding for non standard applications, a substantial improvement in cutting ability and life can be obtained. Please contact Grand Blanc Industries for more information, advice and benefit calculations.Standard Tooth Forms: Image

Retoothing

As a blade is resharpened several times, the tooth pitch is reduced. Therefore it can be necessary to occasionally retooth the blade in order to obtain the correct tooth pitch for the job.This is especially important for high production cutting of tubes.It is easiest done by letting your resharpening service retooth the blades when they reach a set minimum tooth pitch.Pick up

Pick up is one of the most common problems when cutting steel with HSS cold saw blades.Pick up has occurred when bright pieces/deposits of material are welded to the side of the blade. This makes the side of the blade uneven and substantially reduces the cutting ability.Pick up occurs due to friction between the blade and the material.Pick up is especially a problem when cutting stainless.Pick up occurs as a consequence of these cutting conditions:- lack of or wrong cooling/lubrication

- too many teeth in the blade

- too heavy a feed

- lack of cleaning away the chips (brush and fluid)

- lack of cutting ability/grinding

Cutting Brass & Related Materials

Brass is traditionally one of the materials, which demands that the speed and feed are correct. The speed and feed must be relatively high or heavy vibration occurs resulting in blade breakage. For cutting materials not mentioned in this guide, contact your supplier of tools or resharpening.Blade quality

When buying HSS blades, or trying to find the best cold saw blade for your application it is essential to be aware of the following:- The blade must as a minimum be manufactured in M2 quality steel.

- Side run out tolerance should as a minimum not exceed 0.01% of the blade diameter

- Center bore should be H7 tolerance to ensure stisfactory roundness

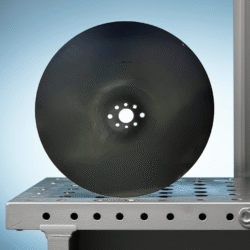

- Blades for general use should have a surface coating such as the standard steam oxide treatment (black surface) to reduce friction

Resharpening quality

Correct resharpening is of extreme importance for the life and cutting ability of a blade.Demands for resharpening include:- correct tooth geometry (tooth pitch, form and depth)

- uniform tooth pitch

- resharpening with coolant

- roundness tolerance max. 30 µ

- correct beveling (tooth form B W and HZ)

- minimal yet adequate resharpening

Cold Saw Blade Guide FAQs

What is a cold saw?

A cold saw is a type of power tool used for cutting metal. It utilizes a circular saw blade with teeth specifically designed for cutting through metal. Unlike other cutting methods, a cold saw operates at a lower RPM (revolutions per minute) and uses a coolant to reduce heat and prevent the material from heating up excessively during the cutting process. The term "cold" refers to the fact that the cutting action doesn't generate significant heat, which helps to preserve the structural integrity of the metal being cut.

How many teeth do you need for a cold saw blade?

Typically, cold saw blades have 60 to 400 teeth.

What does TPI mean on saw blades?

TPI stands for "Teeth Per Inch" on saw blades.

What RPM is a cold cut blade?

A cold cut blade typically operates at a recommended speed of 120 RPM (rotations per minute) or below.

What is tooth pitch for saw blades?

Tooth pitch for saw blades refers to the distance between the tips of two adjacent teeth on the saw blade. It is typically measured in inches or millimeters.

Shop Cold Saw Blades by Saw

Find the right Cold Saw Blades for your Cold Saw

Shop Cold Saw Blades by Size

Cold Saw Blades of the Month

Limited Quantities Available