Did you know that 90% of metalworking errors come from using the wrong cutting tool? The number of edges on your tool is key. It makes all the difference between perfect results and big mistakes. Choosing the right tool setup means smoother cuts, longer tool life, and better project efficiency.

Why is this important? More edges give finer finishes on thin materials like aluminum or sheet metal. Fewer edges work better with thick steel bars, avoiding overheating. The right mix prevents rough edges, cuts down on waste, and saves time.

Think of cutting bread with a sharp knife. The right grooves make clean cuts. Matching your tool’s design to the material thickness is essential. Too many edges on heavy stock can cause friction and wear. Too few on thin sheets might make the finish look bad.

Modern tools combine advanced engineering with design that focuses on the user. Whether making car parts or industrial components, knowing these basics helps you work better. Ready to learn more? Let’s see how geometry, material science, and innovation affect your success.

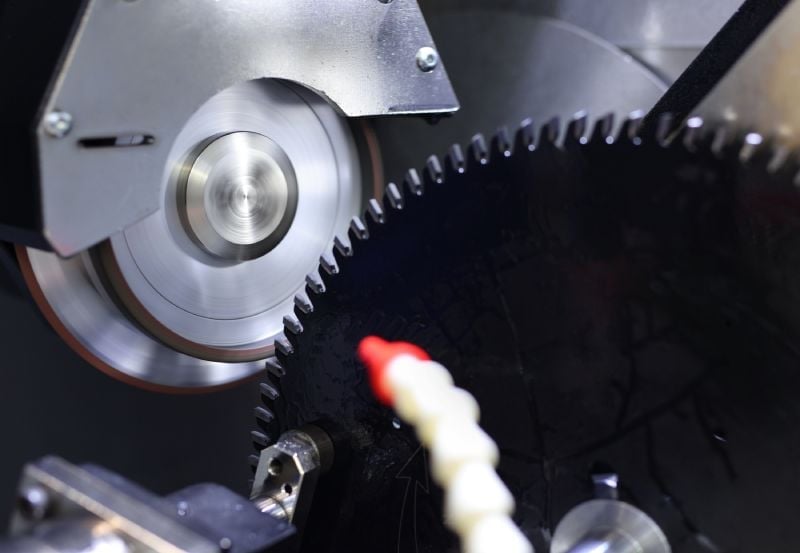

Introduction to Cold Saw Blade Tooth Count

Imagine making a metal piece only to find jagged edges. The key to avoiding this is understanding tooth count. This is the number of cutting edges on your tool. It affects how well the tool works, what materials it can handle, and the final project quality.

What Is Tooth Count?

Tooth count is how many cutting edges a tool has per inch. More edges spread out the cutting force, perfect for thin sheets. Fewer edges are better for thick stock, as they reduce friction. Matching your tool to your workpiece ensures smooth operation and cleaner results.

Why It Matters in Metalworking

Choose wrong, and you risk uneven cuts or tool damage. For example:

- Cutting 1/8″ aluminum? A high count prevents tearing.

- Working with 2″ steel tubing? Fewer teeth clear chips faster.

The right configuration also extends equipment life. Proper spacing prevents overheating, while balanced pressure reduces wear. But how do you match this number to your project’s needs? Let’s explore how material thickness guides your choice.

Understanding Tooth Count and Metal Thickness

Ever struggled with uneven cuts despite using a sharp tool? The solution lies in pairing your material’s thickness with the right saw configuration. Thinner metals demand more cutting edges per inch, while thicker stock requires fewer—but why?

High Tooth Count for Thinner Materials

When you’re cutting sheet metal or aluminum under 1/4″, choose tools with dense edges. This setup spreads pressure evenly. It makes clean cuts without warping delicate surfaces.

For example, blades designed for 22-gauge steel often have 80-100 edges. Each edge removes a little material, keeping control. It’s like using fine-grit sandpaper—precision over power.

Low Tooth Count for Thicker Metals

Working with 1/2″ steel or solid bars? Fewer edges are better. They clear metal chips faster, preventing heat buildup. This lets each edge bite deeper without overheating your tool.

Imagine slicing a dense log: a sharp axe with wide spacing works better than a serrated knife. Blades designed for thick stock prioritize chip removal over surface polish. Choose 24-40 edges for heavy-duty tasks—you’ll finish faster and extend tool life.

Remember: The right saw setup depends on what you’re cutting. Match edge density to material depth, and you’ll avoid costly errors. Need to switch between projects? Keep multiple blades designed for specific thicknesses on hand.

Exploring Different Saw Blade Tooth Configurations

What separates a smooth cut from a messy one? Often, it’s the unseen details—like the geometry of cutting edges. Beyond just the number of teeth, factors like shape, gullet design, and angles determine efficiency and finish quality.

Tooth Shapes, Gullets, and Angles

Flat-top edges excel in slicing thin aluminum, minimizing burrs. Alternate top bevel designs, on the other hand, tackle harder alloys by alternating cutting directions. The gullet—the space between edges—dictates chip clearance. Larger gullets prevent clogging when working with thick steel, while smaller ones suit precision tasks.

Angles matter too. A positive rake angle (leaning forward) bites aggressively into stainless steel, ideal for fast cuts. Neutral angles offer control for brittle materials like cast iron. For example, a 10° positive angle boosts speed, whereas 0° reduces vibration on delicate projects.

Higher tooth counts work best with shallow angles, distributing force across more edges. Fewer edges paired with steep angles handle dense stock efficiently. This balance prevents overheating and extends tool life—critical for repetitive industrial jobs.

Ever notice how some tools leave cleaner finishes on copper pipes? It’s not luck. Matching configurations to material properties ensures predictable results. Prioritize gullet capacity for heavy-duty tasks and edge geometry for fine detail work.

How to Identify the Right Cold Saw Blade for Your Project

Staring at a pile of metal stock? Choosing the ideal cutting tool starts with three critical questions: What are you slicing? How thick is it? What finish quality do you need? Follow this method to align your project with precision equipment.

Step 1: Assess Material Thickness and Finish Goals

Measure your workpiece. Thin sheets (under 1/4″) demand more edges per inch for smooth results. Thick bars require fewer edges to prevent overheating. Prioritize surface polish for visible parts versus speed for structural components.

Step 2: Evaluate Edge Configuration

Look beyond the total count. Check spacing patterns and gullet depth. Tightly packed edges work for aluminum, while wider gaps suit steel. Compare specs like rake angle and bevel type—these impact chip flow and cutting aggression.

| Material Type | Thickness | Recommended Edges | Arrangement |

|---|---|---|---|

| Thin Aluminum | 1/8″ | 80-100 per inch | Alternating bevel |

| Thick Steel | 1″ | 24-40 per inch | Flat-top with deep gullets |

| Stainless Steel | 1/2″ | 60-80 per inch | Triple-chip grind |

| Copper Pipe | 3/4″ | 70-90 per inch | High-positive rake |

Step 3: Compare Manufacturer Specifications

Brands label their products differently. Look at RPM ratings and hardness levels. A disc for non-ferrous metals might have varying edge geometry.

Test samples if you can. Some discs work better with coolant systems.

Final Checklist Before Purchase

– Match edge density to material depth

– Verify heat treatment (HSS or carbide-tipped)

– Confirm compatibility with your machine’s horsepower

– Prioritize chip clearance for thick stock

Pro tip: Keep a reference chart near your workstation. Update it as you test new tools. This makes future decisions easier and saves time.

Material Compatibility in Blade Selection

Choosing the right tool for different metals is key. It’s not just about edge count—it’s about chemistry. The material composition of your cutting disc affects its performance.

Match it to your workpiece for better efficiency and less wear.

Suitable Options for Ferrous Metals

Ferrous metals like steel or cast iron need carbide-tipped or high-speed steel tools. These alloys handle intense heat and abrasion well. For example, cutting 1/2″ stainless steel requires a disc with reinforced edges.

Without this, friction can warp thin sheets or dull edges quickly.

Ideal Choices for Non-Ferrous Materials

Aluminum, copper, and brass require different tools. Softer metals can clog standard tools. Choose discs with polished edges and non-stick coatings.

These reduce buildup and deliver clean cuts on 1/8″ copper pipes or thin aluminum panels. Proper spacing also prevents material from sticking to the surface.

| Material Type | Recommended Composition | Key Features |

|---|---|---|

| Steel/Iron | Carbide-tipped | Heat-resistant, aggressive angles |

| Aluminum | High-speed steel | Polished edges, anti-stick coating |

| Copper | Triple-chip grind | Wide gullets, neutral rake |

Pro tip: Pair your disc with compatible coolants. Water-soluble fluids work for steel, while dry cutting suits aluminum. This combo reduces sparks and extends tool life by 30% in heavy-use settings.

The Role of Tooth Geometry in Achieving Precise Cuts

Precision in metal cutting isn’t just about speed—it’s a dance of angles and edges. The shape and arrangement of each cutting surface determine how cleanly your tool slices through materials. Get this right, and you’ll minimize waste while achieving finishes that need little post-processing.

Bevels, Pitches, and Cutting Angles

Bevel angles create a shearing effect, slicing metal instead of crushing it. For example, alternating top bevels on carbide-tipped edges tackle stainless steel by directing force sideways. This reduces heat and prevents work hardening.

Pitch—the distance between edges—affects how many contact points engage during a cut. Tight spacing works for thin sheets, while wider gaps suit thick stock. A 14° angle might excel on aluminum, but switch to 20° for cast iron to avoid chipping.

Optimizing Rake for Smooth, Clean Cuts

Rake angle determines how aggressively the tool bites into metal. Positive angles (leaning forward) slice faster but risk tearing soft alloys. Neutral angles offer control, ideal for hand-operated tasks where precision matters.

For instance, a +10° rake glides through copper pipes, while 0° keeps brass from deforming. Pair this with the right types of edge coatings, like titanium nitride, to reduce friction on heavy-duty projects.

| Geometry Type | Best For | Performance Benefit |

|---|---|---|

| Alternate Top Bevel | Hardened Steel | Reduces vibration, extends edge life |

| Triple-Chip Grind | Cast Iron | Prevents edge chipping |

| High-Positive Rake | Aluminum | Delivers mirror-like finishes |

Optimizing “saw blade teeth” for Enhanced Performance

Ever wondered why some workshops are more efficient? It’s often because they manage their tools better. This boosts precision, cuts down on downtime, and fits their workflow. It changes how they do projects.

Match Tool Size to Material Demands

Using big tools on thin sheets wastes energy and causes problems. Small, dense edges are best for delicate tasks. For thick materials, bigger tools prevent overheating. Always check the specs to match your work.

Maintenance Matters

Dull edges cause friction, leading to bad cuts and wear. Clean tools after each use to remove metal. Lubricate often, more so for alloys that gum up surfaces. A well-kept setup lasts 40% longer, saving money.

Adjust your tools based on your shop’s needs. For lots of production, focus on quick chip removal and heat resistance. For custom work, sharp edges are key for detailed designs. Rotate tools to spread wear evenly.

| Shop Size | Maintenance Frequency | Key Tasks |

|---|---|---|

| Small | Weekly | Clean edges, check alignment |

| Medium | Every 3 days | Lubricate, inspect for chips |

| Large | Daily | Full calibration, coolant checks |

Sync these practices with your team’s routine. Schedule inspections during shift changes, and train staff to spot early signs of wear. When tools and workflows align, you’ll see smoother operations and consistent results across every project.

Benefits of a Higher Tooth Count for Clean, Precise Cuts

Achieving mirror-like finishes on metal projects requires tools designed for accuracy. Higher-density configurations excel here, especially when working with thin steel or aluminum sheets. These setups distribute cutting force across more edges, reducing pressure on individual points.

Why choose this type for precision tasks? More edges create smoother surfaces by making smaller, controlled bites. For example, slicing 18-gauge stainless steel tubing leaves minimal burrs when using 100+ edges per inch. This reduces post-processing time and material waste by up to 25%.

- Sharper finishes: High-density tools polish surfaces as they cut.

- Reduced vibration: Even force distribution prevents chatter.

- Longer lifespan: Carbide tips maintain sharpness 3x longer than standard options.

Compare this to lower configurations: Fewer edges struggle with thin materials, often tearing delicate sheets. However, they’re ideal for thick stock where chip clearance matters most. Matching the type to your workpiece ensures optimal results.

| Application | Edge Count | Finish Quality | Best For |

|---|---|---|---|

| Thin Aluminum | 80-100 | Mirror-like | Automotive panels |

| 1/2″ Steel | 40-60 | Smooth | Structural beams |

| Stainless Tubing | 100+ | Burr-free | Medical equipment |

Carbide tips are very hard. They can cut through tough materials without wearing down. This is great for places that use tools a lot every day.

Using them right means you can make cuts over and over again. You’ll get the same quality every time.

Real shops have seen big improvements. One aerospace company cut down on mistakes by 40% when they started using these tools for titanium. Another shop cut aluminum faster by 30% and made it look better. The right type of tool really makes a difference.

Cold Saw Blade Advancements and Emerging Technologies

Metalworking tools are getting better fast. New materials and coatings help solve old problems like heat and wear. These new tools let you cut cleaner, work longer, and take breaks less often. You can keep precision without any trouble.

Revolutionary Coatings for Peak Performance

Titanium and zirconium nitride coatings are leading the way. They’re very thin but cut friction by up to 50%. This means you can cut through aluminum or stainless steel without getting too hot.

Tests show these tools last 3x longer, even in busy shops. Why is this important? Less heat means you won’t warp thin materials. For example, cutting 1/8″ aluminum sheets leaves smoother edges. You’ll spend less time fixing edges and more time putting things together.

- Faster cuts: Low-friction coatings let you increase feed rates safely.

- Wider material choice: Handle abrasive alloys like titanium without frequent tool changes.

- Eco-friendly option: Some coatings eliminate the need for cutting fluids, reducing waste.

These advancements make choosing easier. Now, one tool can handle many projects. A company in aerospace cut their inventory by 30% with multi-purpose tools.

Modern coatings are smarter for tough tasks. They help in making prototypes or large quantities.

Comparing Full Kerf and Thin Kerf Blades for Your Saw

Deciding between full and thin kerf blades can be tough. The kerf is how much material is cut. Full kerf cuts more, thin kerf cuts less.

Impact on Efficiency and Motor Performance

Thin kerf tools need less power. They’re great for small motors, saving up to 25% energy. Full kerf tools are strong for heavy tasks but need more power.

Think about your projects. Need to cut hard woods? Full kerf is best. For plywood or laminates, thin kerf is better. Match your power needs with your project’s finish.

| Feature | Full Kerf | Thin Kerf |

|---|---|---|

| Kerf Width | 1/8″ | 3/32″ |

| Motor Load | High | Low |

| Cut Quality | Stable | Precise |

| Best For | Hardwoods | Delicate materials |

Thin kerf tools are great for detailed work but can bend under pressure. Full kerf blades stay stiff and cut less vibration. Always check your tool’s power before choosing. This comparison guide makes choosing easier.

Pro tip: Use thin kerf with lots of teeth for perfect veneer finishes. Choose full kerf for beams where speed is key.

Conclusion

Your project’s success depends on precision. Match edge density to material thickness. Use thin kerf blades for fine work and full kerf for beams.

Modern coatings let you cut better without losing quality. Choose high-density edges or special gullet designs. Balance old and new methods to save time and materials.

Ready to improve your work? Check teeth per inch, heat resistance, and chip clearance before cutting. Keep a reference chart for easy decisions.

Understanding edge count and geometry makes cuts better. Your shop’s efficiency depends on it.

FAQ

How does the number of teeth impact cut quality in metalworking?

More teeth make smooth finishes on thin sheets. Fewer are better for thick stock. The right count reduces heat and tool wear.

What happens if I use a high-tooth blade on thick materials?

Too many teeth can cause friction, overheating, or wear. Lower counts clear chips faster, helping with dense metals like steel.

How do I match a blade to ferrous vs. non-ferrous metals?

Carbide-tipped blades work well on hardened steel and alloys. Aluminum or copper need blades with anti-stick coatings and sharp angles.

Why does tooth geometry matter beyond just the count?

Bevel angles and gullet depth affect chip removal and vibration. For example, triple-chip designs reduce burrs on stainless steel. Variable pitches lower noise.

When should I choose a thin kerf over a full kerf design?

Thin kerf is good for small motors and less waste. Full kerf is stable for heavy-duty work.

Can advanced coatings improve blade performance?

Yes. Coatings like titanium nitride (TiN) or ceramic make blades last longer, reduce heat, and resist corrosion. They’re great for tough materials.

What’s the easiest way to avoid blade binding during cuts?

Make sure tooth spacing matches the material’s thickness. Too few teeth on thin stock can snag. Too many on thick stock trap chips.

How often should I replace or sharpen my cold saw blade?

Check edges often for dullness or chipping. Sharpening needs vary by use. But, if you feel vibration or see rough finishes, it’s time.