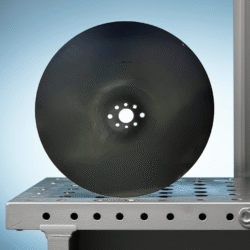

Aluminum & Non-Ferrous Metals

Cold saw blade guide to cutting aluminum & non-ferrous metals

Soft metals like aluminum require a different blade setup than steel — especially when it comes to tooth geometry, coating, and kerf thickness. Whether you’re cutting window frames, downspouts, or a solid bar, we’ll help you achieve the cleanest cuts with the longest blade life — tailored to your machine and material.

Bestselling Blades

What Type of Saw Are You Using?

🛠 Manual Cold Saw (Under 120 RPM)

For cutting aluminum on a manual cold saw, we recommend only one blade type:- TiN Coated M2 Cold Saw Blades for Aluminum

These blades are perfect for the job when paired with the correct grind geometry — which we configure at the time of manufacture. When you select “aluminum” at checkout, we’ll grind the blade to 25° rake / 12° relief, which is ideal for clean cuts and chip evacuation in non-ferrous metals.

Note: Upgrading to M35 or TIALN for aluminum isn’t necessary on a manual saw. Blade life improvement is minor, and performance differences are rarely noticeable.

Optional Add-On: If you’re using a manual saw without flood coolant or mist lubrication, we recommend applying a wax stick lubricant directly to the blade before cutting. This helps prevent aluminum from gumming up the blade and improves cut quality and blade life.

⚙️ Semi-Automatic Cold Saw (Under 120 RPM)

- TiN Coated M2 Cold Saw Blades for Aluminum

Tooth Count Tip: If you’re using our Tooth Count Calculator, reduce the result by 30% for aluminum. A lower tooth count means larger gullets, better chip flow, and less clogging.

🪚 Woodworking Saws (Chop, Miter, Table, Radial Arm)

- Carbide-Tipped Non-Ferrous Metal Blades (TCG)

These blades feature Triple Chip Grind (TCG) with hook angles of 5°, 0°, or +5°, depending on the application. They provide clean, burr-free cuts in extrusions, bar stock, and profiles.

Pro Tip: For woodworking and dry-cut saws without misting systems, we recommend using a non-ferrous cutting wax stick to reduce heat, minimize burrs, and extend the life of both carbide-tipped and bright finish blades.

Double Miter & Up-Cut Aluminum Saws

- Carbide-Tipped TCG Blades

These saws are common in aluminum window and door frame shops. Carbide-tipped blades are the go-to choice in nearly all of these high-output applications. We stock carbide-tipped blades for cutting aluminum in diameters from 3 inches up to 30 inches with all sorts of arbor holes, pinholes, and numbers of teeth to fit different machines and applications.

✨ HSS “Bright” Blades for Thin-Gauge Extrusions & Fragile Shapes

- Bright Finish M2 HSS Blades (58 HRC)

These blades have a thinner kerf and are only hardened to around 58 HRC to reduce brittleness. Ideal for fragile aluminum and copper shapes like:

- Screen door frames

- Window extrusions

- Downspouts

- Roll-formed aluminum profiles

- Thin copper tubing

These blades work great on woodworking saws like chop, table, radial arm, and double miter saws.

🧴 Lubrication Tip for Aluminum Cutting

If your saw doesn’t have mist or flood lubrication, use our aluminum cutting wax stick to:

- ✅ Improve surface finish

- ✅ Reduce gumming and loading

- ✅ Extend blade life for both carbide-tipped and bright finish HSS blades

Blade Selection Summary

| Saw Type | Recommended Blade | Notes |

|---|---|---|

| Manual Cold Saw | TiN Coated M2 (25°/12° grind) | Use wax if no coolant system |

| Semi-Auto Cold Saw | TiN Coated M2 (25°/12° grind) | Reduce tooth count by 30% |

| Woodworking Saws | Carbide-Tipped Non-Ferrous Blades (TCG) | Use wax to reduce gumming |

| Double Miter / Up-Cut Saws | Carbide-Tipped TCG Blades | Ideal for aluminum profile production |

| Thin & Fragile Profiles | Bright Finish M2 HSS Blades (58 HRC) | Thinner kerf for delicate applications |