Mild Steel & Structural Tubing

Cold saw blade guide to cutting mild steel & structural tubing

Cold Saw Blades perform best when matched to your saw’s speed (RPM) and the material you’re cutting. Whether you run a manual cold saw, a semi-auto production machine, or a dry-cut portable saw, the right saw blade reduces chatter, prevents premature wear, and delivers cleaner cuts.

This guide quickly walks you through blade choices by machine type and application, enabling you to extend blade life, improve cut quality, and make more informed purchasing decisions for cold saw blades and replacement blades.

What you’ll learn:

- Which blade types work with specific cold saw machines and RPM ranges

- When to choose HSS (M2), cermet, or carbide-tipped blades

- Quick tips to match blade thickness and tooth count for cleaner cuts and better value

Need help selecting a new blade or checking price and availability? Contact us — we’ll recommend the right blade for your saw and material.

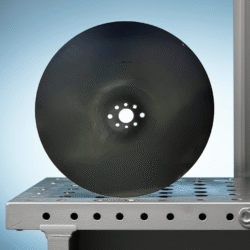

Bestselling Blades

What Type of Saw Are You Using?

🛠 Manual Cold Saw (Under 120 RPM)

Manual cold saws are low-speed, operator-fed machines used in fab shops and maintenance departments. For general-purpose mild steel cutting, you want a high-quality cold saw blade that balances toughness and edge retention.

- RPM Range: 20–120 RPM

- Feed Type: Manual

- Blade Type: HSS options such as M2 with black oxide or TiN for longer life

- Best For: Thin- and medium-wall tubing, angle, flats, and solid bar

Tip: Match blade thickness and tooth count to the material. Typical recommendations: 2.0mm blade thickness for thin-wall tubing, 2.5mm for general cuts, and 3.0mm for solid or heavy-wall stock.

⚙️ Semi-Automatic & Automatic Cold Saws (Under 120 RPM)

Semi-auto and fully automatic cold saw machines use hydraulic or pneumatic feeds for consistent pressure and higher throughput. Because heat and chip load are higher, blade coating and geometry make a measurable difference in life and cut quality.

- RPM Range: 50–120 RPM (typical)

- Feed Type: Hydraulic or pneumatic (servo on fully automatic lines)

- Blade Type: TIALN or similar high-temperature coatings is strongly recommended for production runs

- Best For: High-volume cutting of tube, angle, and bar stock

Tip: Use flood coolant, optimize feed rate for the material, and pick a blade geometry designed for consistent chip evacuation to reduce heat buildup and extend blade life.

⚡ Dry-Cut Metal Saws / Evolution-Style (1,300–1,500 RPM)

High-RPM dry-cut saws (brands like Evolution, DeWalt, Slugger, Makita) require carbide-tipped blades specifically rated for elevated speeds. These are portable or light-fab tools where coolant is typically not used.

- RPM Range: 1,300–1,500 RPM

- Feed Type: Manual

- Blade Type: Carbide-tipped blades rated for high RPM only — do not use HSS

- Best For: EMT conduit, Unistrut, angle iron, mild steel tubing on job sites

Important: HSS blades are not rated for these speeds and will rapidly fail. Always choose a carbide-tipped saw blade with the correct RPM rating and follow the manufacturer’s safety guidance.

🔥 Friction Saw or Hot Saw (3,000–6,000 RPM)

Friction or hot saws cut with heat and speed using abrasive or solid friction discs. These machines and blades are a different technology from cold saws and require abrasive consumables.

- RPM Range: 3,000–6,000 RPM

- Blade Type: Abrasive wheels or solid friction blades only

- Not Compatible: HSS or carbide cold saw blades — they will disintegrate and are unsafe

Warning: Never install a cold saw blade on a friction saw. It’s unsafe, will destroy the blade, and risks operator injury.

🧪 Cermet-Tipped CNC Saws (Amada, Nishijimax, Tsune, Kasto, Behringer)

High-precision, servo-driven CNC saws in production lines often use cermet-tipped blades designed for tight tolerances and long life. These are different from standard HSS and carbide solutions and are specified by OEMs.

- RPM Range: 50–250 RPM (depends on machine and material)

- Feed Type: Fully automatic (servo-controlled)

- Blade Type: Cermet-tipped blades specified for the machine — not HSS or standard carbide

- Best For: High-volume tube, bar, and profile cutting where tolerance and tool life are critical

Tip: Match chip load, RPM, and cermet geometry carefully. Consult your machine OEM or our Cold Saw Blade Store specialists to select the correct cermet blade for your model and production rate.

🤷 Not Sure What You Have?

If you can’t identify your saw or need help matching blades, our Cold Saw Blade Store specialists will recommend the best cold saw blade, compatible options, and pricing. We help shops and fabricators find blades that fit cold saw machines of every brand and model.

- Call: (800) 397-8511

- Email: info@coldsawbladestore.com

Tip: Send a photo of your saw (include model plate if possible), the material you’re cutting, and desired daily output — our team will propose blades that fit your saw, shipping options, and an order/price estimate (typical response within one business day).