Did you know a dull cold saw blade can cut efficiency by up to 30%? This big drop affects your cut quality and raises costs over time. Knowing when to sharpen your cold saw blade is key for keeping it sharp and precise.

Cold saw blades are vital in many industries, and keeping them in good shape is essential. Regular use wears them down, and spotting a dull blade early can prevent bigger problems. Timely sharpening is vital for smooth operations and avoiding expensive fixes.

Seeing your blade’s performance drop or struggling with materials it used to cut easily means it’s time for sharpening. Well-maintained blades keep your machine running smoothly and protect you from accidents caused by dull blades.

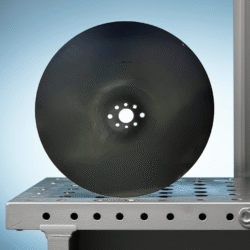

Best Selling Cold Saw Blades

In the next parts, we’ll explore the signs that show when a cold saw blade needs sharpening. We’ll also talk about why precision sharpening is important for safety and efficiency.

Signs Your Cold Saw Blade Needs Sharpening

Keeping your cold saw blade in top shape is key. Spotting wear early can save you money and keep things running smoothly. Here are the main signs it’s time to sharpen your blade.

The Blade Requires Excessive Pressure

Need to push harder to cut? That means your blade is dull. A dull blade makes work harder and can be dangerous. To avoid these problems, sharpen your blade on time.

The Blade Teeth Look Rounded

Check if the blade teeth look rounded or bent. Sharp teeth are essential for clean cuts. If they’re not sharp, it’s time for circular saw blade sharpening to fix them.

The Cut Edges Appear Rough

Rough edges on your cuts mean the blade is dull. This affects the quality of your work. Getting your blade sharpened by industrial saw blade sharpening experts can help.

The Saw Operates Louder Than Usual

Does your saw sound louder than usual? That’s a sign of trouble. Struggling to cut makes more noise. If your saw is too loud, it’s time for metal cutting blade repair to fix it.

Understanding the Importance of Cold Saw Blade Sharpening

Keeping your cold saw blade sharp is key for efficient and safe cutting. Regular sharpening boosts performance and extends blade and saw life. Let’s explore the benefits of sharpening and why it’s vital for your cutting needs.

Ensures Precise and Efficient Cuts

A sharp blade means precise and efficient cuts. This ensures a high-quality finish for tough tasks. Regular cold cut saw blade sharpening keeps cuts accurate and clean. This reduces waste and saves time.

Keeps Machine Operation Safe

Blade sharpening also boosts safety. A sharp blade lowers the risk of kickbacks and other dangers. Using the best saw blade sharpening service ensures safe and effective operation.

Helps Maintain Your Saw

Regular sharpening eases stress on the saw’s motor and parts. This is key to extending the saw’s life and preventing early wear. Professional cold saw blade sharpening keeps your saw in prime condition, avoiding expensive repairs and downtime.

Hire a Professional Sharpening Service

For the best sharpening results, go for a professional service. They have the skills, tools, and knowledge to sharpen blades right. Relying on top cold saw blade sharpening services ensures your blades last longer and work better, letting you work without interruptions.

Remember, investing in professional services for cold cut or carbide saw blade sharpening is worth it. It keeps your cutting efficient and extends blade life.

Conclusion

Knowing when to sharpen a cold saw blade is key. It affects the quality of your cuts, safety, and how long your equipment lasts. Signs like needing more pressure, teeth getting rounded, and rough edges mean it’s time to sharpen.

Keeping your cold saw blade sharp is important. It helps with accurate cuts and keeps your equipment running smoothly. Getting your blade sharpened by experts is a smart choice. It ensures your cuts meet high standards.

Choosing the best cold saw blade sharpening service is wise. It keeps you safe and improves your work quality. Many top services offer quality sharpening at good prices. This is great for both hobbyists and professionals. The right maintenance keeps your cold saw blades safe, precise, and efficient.

When does a cold saw blade need sharpening?

You’ll know it’s time to sharpen your cold saw blade when it starts to cut poorly. This means you need to push harder, the cuts are uneven, and the saw sounds louder. Also, look for wear on the blade teeth. Keeping it sharp is key for good performance and safety.

What are the signs that my cold saw blade needs sharpening?

Here are some signs your blade might need sharpening:

- The blade requires excessive pressure to cut.

- The blade teeth look rounded or deformed.

- The cut edges appear rough and jagged.

- The saw operates louder than usual.

Why is it important to sharpen my cold saw blade regularly?

Sharpening your cold saw blade regularly is important for many reasons:

- It ensures precise and efficient cuts.

- Keeps the saw operation safe and minimizes risks like kickbacks.

- Helps maintain the longevity and performance of your saw.

- Prevents costly repairs or replacements by reducing undue stress on the saw’s components.

How does sharpening enhance the precision of cuts?

Sharpening makes the blade sharp again, allowing for clean cuts. This is essential for high-quality finishes in precise applications.

What role does sharpening play in the safety of operating a cold saw?

A sharp blade reduces the risk of kickbacks and other dangers. This keeps the operator safe and makes the work environment safer.

How does maintaining a sharp blade contribute to the longevity of my saw?

A sharp blade puts less strain on the saw’s motor and parts. This helps your saw last longer and prevents early wear and tear.

Should I hire a professional sharpening service for my cold saw blade?

Yes, it’s a good idea to hire a professional. They have the skills, tools, and knowledge to keep your blade sharp. This helps keep your blade cutting well and lasts longer.

Can regular maintenance of my cold saw blade impact its overall performance?

Absolutely. Keeping up with maintenance, like sharpening, is vital. It keeps the blade sharp, precise, and safe. It also prevents damage that could cost a lot to fix.

What are the benefits of professional cold saw blade sharpening services?

Professional services offer many benefits:

- Expertise in precision blade sharpening.

- Access to advanced tools and techniques.

- In-depth understanding of different blade types and their maintenance needs.

- Guaranteed optimal sharpening outcomes and extended blade life.